English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

Products

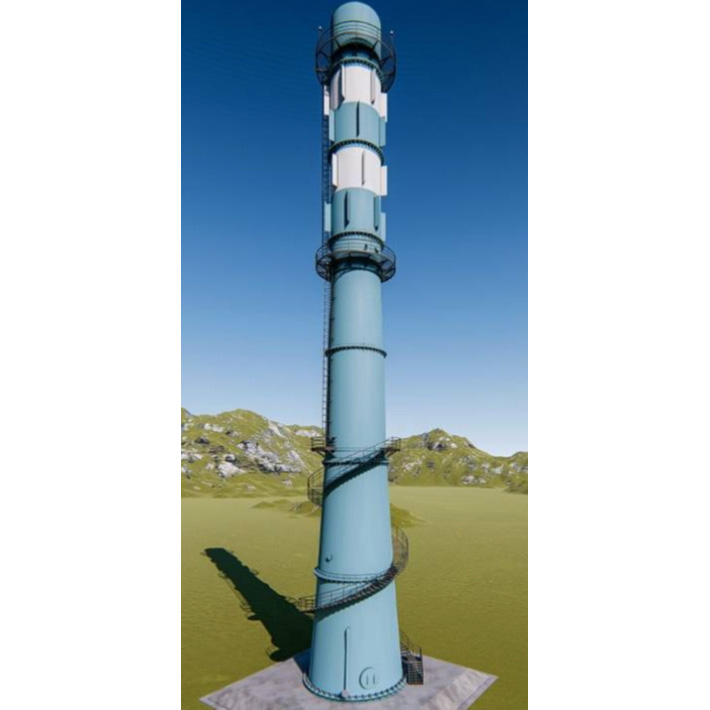

Chemical Plant Free Standing Steel Chimney

Hebei Pude Yueland Environmental Protection Equipment Co., Ltd. is a professional engaged in industrial chemical plant free standing steel chimney research and development, production of manufacturers and factories. The company focuses on the development and production of industrial chimneys.

Send Inquiry

Product Description

Making scheme of Chemical Plant Free Standing Steel Chimney

1.Material reception and requirements: The steel used in the production of steel chimney should be accompanied by a steel quality certificate, the indicators should meet the requirements of the design document and the current national standards, unqualified materials are prohibited to use. Line lead retest the vertical point of the chimney center, confirm correct before subsection connection, to prevent the chimney site installation due to different heart and safety risks. All the welding joints are broken by unit type. When welding, the weld is full without porosity, and the surface forming degree is smooth and flat. The welding personnel must have the welder qualification certificate issued by the national security department, and it is strictly prohibited to work without a certificate.

2.The electrode must have the product certificate and date, in line with the national "carbon steel electrode" standard provisions, welding before the electrode should be oven drying treatment.

2.The electrode must have the product certificate and date, in line with the national "carbon steel electrode" standard provisions, welding before the electrode should be oven drying treatment.

Haulage Chemical Plant Free Standing Steel Chimney:

1.The chimney loading needs to use a long ultra-wide truck, in the bottom of the truck according to the chimney conical external size welded anti-skateboard with a hand hoist to tighten the wire rope, in the binding of the wire rope with a soft mat.

2.The goods to the construction site, it is strictly prohibited to use forklift, forklift unloading. The crane should be used to safely unload the cargo in the correct lifting manner.

2.The goods to the construction site, it is strictly prohibited to use forklift, forklift unloading. The crane should be used to safely unload the cargo in the correct lifting manner.

Chemical Plant Free Standing Steel Chimney installation scheme:

1. Before the chimney installation and lifting, the on-site technical supervisor shall submit the commencement report to Party A in advance, and organize the construction personnel to observe the site surface and surrounding buildings to make all preparations for the hoisting and installation.

2. Check the basic drawings and arrange technical personnel to test the horizontal point and center point of the foundation, so as to ensure that the chimney is not affected by wind and bad weather and can be used normally.

3. Before installing the cylinder body, use the crane to hang the upper taper of the chimney so that it is left or right from the ground. Note: In the process of chimney hoisting, to prevent the chimney deformation, it is strictly prohibited to use wire rope, special sling is required for lifting, in the conical degree of the mouth down about meters, with flat iron and Angle steel, in the Angle steel hole, easy to hang the outer foot triangular bracket, with full teeth bolts will be made of flat iron hoop hold tight to the chimney, and around the hoop with steel rope around two tight, A lanyard used as a seat belt.

4. According to the average spacing of each circumference inside the upper mouth of the chimney vertebra, weld the right-triangle iron plate about the thickness to facilitate the installation of the next section of the chimney and the butt of the chimney.

5. When the first section of the cylinder is installed after all the preparatory work is done, the truck crane is used for lifting and installation. The lifted chimney is placed on the foundation valve blue plate, and the center point is identified and then clicked and welded. After welding the bottom of the chimney, weld the height, width and thickness of the reinforcing plate in equal parts.

6. After welding the bottom of the chimney, the spare ladder made in advance shall be welded and fixed in a cross way according to the average calculation of each grid, and the climbing operation shall begin.

7. After putting on the safety hat and tying the safety rope, the climbing welding personnel should wear a loading rope and climb to the top of the chimney, hang up the pulley, and the ground personnel should pull the long and wide boards of the outer feet and hands to the top of the chimney. After being supported by the climbing personnel, they should gently put them on the triangular supports of the outer feet and hands and bind them.

8. When hoisting the second chimney, due to the lack of crane height, it is necessary to use the above crane to lift and install the second chimney on the top of the first chimney. When docking, it is necessary to hoist the vertical line of the center of gravity of the chimney.

9. Due to the bumps in the car during transportation, the chimney may be slightly deformed. If there is any dislocation during docking, iron plug and mechanical roof shall be used to correct it. Welding shall be carried out according to the requirements of welding specifications. After cooling, the antirust primer and top coat shall be applied again to hoist the third section cylinder.

Hebei Pude Yuelan Environmental Protection Equipment Co., Ltd. is an enterprise engaged in the development and production of industrial chimneys, the company focuses on the development and production of industrial chimneys.

Headquartered in Jingxian Development Zone, Hebei Province, the company has a registered capital of 60 million yuan, covers an area of 9.60000 square meters, of which the building area is 2600 square meters. The main products include self-supporting smoke, sleeve smoke, tower chimney, east smoke, cable smoke, stainless steel chimney, glass steel chimney, mobile compressed garbage bin, horizontal compressed garbage station, hook arm transfer truck, butt type garbage truck and dozens of products. The company has 128 employees, including 8 experts and engineers with master's degree or above, 60% of the employees with bachelor's degree or junior college degree, all kinds of technical personnel 26 people, 60 people special personnel, the company has a number of domestic offices and after-sales service institutions, can provide technical support and product services at any time.

The company's production equipment advanced, strong technical force. Has more than 50 sets of domestic advanced production equipment, including foreign, domestic CNC production lines 6; Hot-dip galvanizing adopts the galvanizing technology and process of Gimeco Company in Italy, and its technical level and production capacity are at the advanced level in China.

After years of development in chimney and municipal waste treatment equipment industry, the company has become a well-known brand in the industry. Through the cooperation with domestic and international design institutes, colleges and enterprises to continuously improve the enterprise's scientific research and development ability. And has cooperated with many universities and reached strategic cooperation with petrochina, Sinopec, Huadian, Huaneng and other enterprises.

In recent years, in order to solve the problem of large-caliber smoke, the company has established a technical cooperation relationship with Beijing Jiaotong University, and invested a lot of manpower and material resources to develop the "precast factory, on-site construction" steel corrugated chimney and urban waste environmental treatment products. At present, the pipe diameter range of the company's products is 0.5m-20m, and the annual production capacity is 660,000 meters.

The company always adhere to the "quality, user" of the enterprise purpose, do not ask for the number of projects, just do the project to make good quality principle, products have been promoted in the project use. Today, the company's products still maintain zero defects, zero complaints, zero accidents, by the owners, construction units of the consistent praise, and establish a long-term cooperative relationship.

2. Check the basic drawings and arrange technical personnel to test the horizontal point and center point of the foundation, so as to ensure that the chimney is not affected by wind and bad weather and can be used normally.

3. Before installing the cylinder body, use the crane to hang the upper taper of the chimney so that it is left or right from the ground. Note: In the process of chimney hoisting, to prevent the chimney deformation, it is strictly prohibited to use wire rope, special sling is required for lifting, in the conical degree of the mouth down about meters, with flat iron and Angle steel, in the Angle steel hole, easy to hang the outer foot triangular bracket, with full teeth bolts will be made of flat iron hoop hold tight to the chimney, and around the hoop with steel rope around two tight, A lanyard used as a seat belt.

4. According to the average spacing of each circumference inside the upper mouth of the chimney vertebra, weld the right-triangle iron plate about the thickness to facilitate the installation of the next section of the chimney and the butt of the chimney.

5. When the first section of the cylinder is installed after all the preparatory work is done, the truck crane is used for lifting and installation. The lifted chimney is placed on the foundation valve blue plate, and the center point is identified and then clicked and welded. After welding the bottom of the chimney, weld the height, width and thickness of the reinforcing plate in equal parts.

6. After welding the bottom of the chimney, the spare ladder made in advance shall be welded and fixed in a cross way according to the average calculation of each grid, and the climbing operation shall begin.

7. After putting on the safety hat and tying the safety rope, the climbing welding personnel should wear a loading rope and climb to the top of the chimney, hang up the pulley, and the ground personnel should pull the long and wide boards of the outer feet and hands to the top of the chimney. After being supported by the climbing personnel, they should gently put them on the triangular supports of the outer feet and hands and bind them.

8. When hoisting the second chimney, due to the lack of crane height, it is necessary to use the above crane to lift and install the second chimney on the top of the first chimney. When docking, it is necessary to hoist the vertical line of the center of gravity of the chimney.

9. Due to the bumps in the car during transportation, the chimney may be slightly deformed. If there is any dislocation during docking, iron plug and mechanical roof shall be used to correct it. Welding shall be carried out according to the requirements of welding specifications. After cooling, the antirust primer and top coat shall be applied again to hoist the third section cylinder.

Hebei Pude Yuelan Environmental Protection Equipment Co., Ltd. is an enterprise engaged in the development and production of industrial chimneys, the company focuses on the development and production of industrial chimneys.

Headquartered in Jingxian Development Zone, Hebei Province, the company has a registered capital of 60 million yuan, covers an area of 9.60000 square meters, of which the building area is 2600 square meters. The main products include self-supporting smoke, sleeve smoke, tower chimney, east smoke, cable smoke, stainless steel chimney, glass steel chimney, mobile compressed garbage bin, horizontal compressed garbage station, hook arm transfer truck, butt type garbage truck and dozens of products. The company has 128 employees, including 8 experts and engineers with master's degree or above, 60% of the employees with bachelor's degree or junior college degree, all kinds of technical personnel 26 people, 60 people special personnel, the company has a number of domestic offices and after-sales service institutions, can provide technical support and product services at any time.

The company's production equipment advanced, strong technical force. Has more than 50 sets of domestic advanced production equipment, including foreign, domestic CNC production lines 6; Hot-dip galvanizing adopts the galvanizing technology and process of Gimeco Company in Italy, and its technical level and production capacity are at the advanced level in China.

After years of development in chimney and municipal waste treatment equipment industry, the company has become a well-known brand in the industry. Through the cooperation with domestic and international design institutes, colleges and enterprises to continuously improve the enterprise's scientific research and development ability. And has cooperated with many universities and reached strategic cooperation with petrochina, Sinopec, Huadian, Huaneng and other enterprises.

In recent years, in order to solve the problem of large-caliber smoke, the company has established a technical cooperation relationship with Beijing Jiaotong University, and invested a lot of manpower and material resources to develop the "precast factory, on-site construction" steel corrugated chimney and urban waste environmental treatment products. At present, the pipe diameter range of the company's products is 0.5m-20m, and the annual production capacity is 660,000 meters.

The company always adhere to the "quality, user" of the enterprise purpose, do not ask for the number of projects, just do the project to make good quality principle, products have been promoted in the project use. Today, the company's products still maintain zero defects, zero complaints, zero accidents, by the owners, construction units of the consistent praise, and establish a long-term cooperative relationship.

Hot Tags:

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy