English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

Products

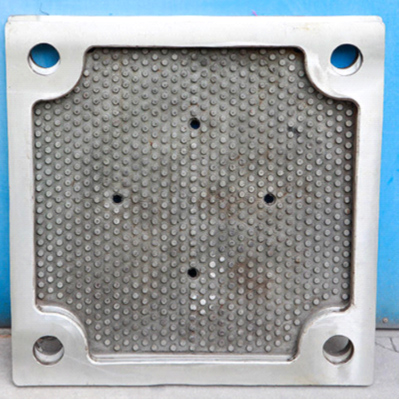

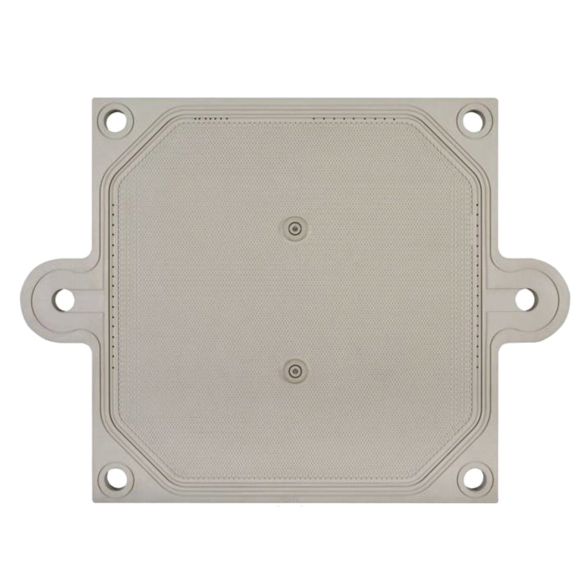

Polyethylene Filter Plate

The service life of ultra-high molecular polyethylene filter plate is 2-3 times higher than that of polypropylene filter plate, 3-9 times higher than that of cast iron filter plate. Ultra-high molecular polyethylene filter plate has the advantages of light weight, fast dehydration, wear resistance, environmental cracking resistance, good stability, high compressive strength, not easy to bond with other materials, long service life, small loss of press cloth, flexible operation, convenient maintenance and so on.

Send Inquiry

Product Description

Especially cloth pressure ring, ultra high molecular polyethylene filter plate, novel and scientific design, can not only prevent the filter plate deformation and cracking, but also play the role of reasonable dispersion into the material. At present, ultra-high molecular weight polyethylene filter plate has been widely used in mining, coal preparation, chemical industry, metallurgy, food, medicine, oil refining, sugar production, wastewater treatment and other fields. Ultra high molecular polyethylene filter plate is cast iron, rubber polypropylene filter plate ideal replacement products.

Ultra-high molecular weight polyethylene filter plate is a new type of efficient and energy-saving filter plate after the cast iron filter plate, rubber filter plate, polypropylene filter plate, it has fast dehydration, corrosion resistance, environmental cracking resistance, high compressive strength, impact resistance, light weight, anti-bonding, convenient installation and maintenance, small loss to the filter cloth, long service life and other advantages, the service life is 4-6 times of polypropylene filter plate, Cast iron and rubber filter plate 3-9 times.

Due to the light weight of ultra-high molecular weight polyethylene filter plate (is one eighth of the cast iron filter plate), greatly reduce the load of the filter press girder, prevent the bending deformation of the girder because of the weight of the filter plate, prolong the service life of the girder. The lower pressure of the puller mechanism reduces the impact strength of the filter plate on the press cloth, improves the service life and work efficiency of the puller, press cloth and related hydraulic system, and reduces the labor intensity and maintenance cost of maintenance workers.

UHMWPE extremely high molecular weight gives it excellent performance, and belongs to moderate price, excellent performance of thermoplastic engineering plastics, it almost concentrated the advantages of a variety of plastics, With ordinary polyethylene and other engineering plastics incomparable wear resistance, impact resistance, self-lubrication, corrosion resistance, impact absorption, low temperature resistance, health and non-toxic, not easy to adhere to, not easy to absorb water, low density and other comprehensive properties. In fact, there is no single polymer material with so many excellent properties.

1. High molecular weight

The wear resistance of UHMWPE is the crown of plastics and exceeds that of some metals. The comparison of the wear resistance of UHMWPE and other materials. Compared with other engineering plastics, the sand abrasion index of UHMWPE is only 1/5 of PA66, and 1/10 of HEPE and PVC. Compared to metal, it's 1/7 of carbon steel and 1/27 of brass. Such high wear resistance makes it difficult to test its wear resistance with general plastic wear test method, so a sand abrasion test device is specially designed. The wear resistance of UHMWPE is proportional to the molecular weight, the higher the molecular weight, the better the wear resistance.

2. Extreme impact resistance

The impact strength of UHMWPE is among the best in all engineering plastics. The impact strength of UHMWPE is about 2 times that of impact resistant PC, 5 times that of ABS, and more than 10 times that of POM and PBTP. The impact resistance is so high that it is difficult to fracture by the usual impact test methods. The impact strength increased with the increase of molecular weight, reached the maximum value when the molecular weight was 1.5 million, and then gradually decreased with the increase of molecular weight. It is worth pointing out that it can also maintain excellent impact strength in liquid nitrogen (-195℃), which is not found in other plastics. In addition, it is harder on repeated impact surfaces.

3. Ideal friction

UHMWPE has very low friction coefficient (0.05 ~ 0.11), so it has excellent self-lubrication. The comparison of friction coefficient between UHMWPE and other engineering plastics. UHMWPE dynamic rub factor under water lubrication is PA66 and POM 1/2, under no lubrication conditions second only to plastic in the best self-lubricating polytetrafluoroethylene (PTFE); When it is operated in sliding or rotating form, it is more lubricated than steel and brass with oil. Therefore, in the field of tribology, UHMWPE is regarded as a frictional material with very ideal cost/performance.

4. Chemistry

UHMWPE has excellent chemical resistance, in addition to strong oxidizing acid, in a certain temperature and concentration range of corrosive media (acid, alkali, salt) and organic media (except tea solvent). It was impregnated in 80 organic solvents at 20℃ and 80℃ for 30 days. There was no abnormal appearance and other physical properties were almost unchanged.

5. Silence the sound well

UHMWPE has excellent impact energy absorption, the impact energy absorption value is the highest among all plastics, so the noise damping performance is very good, and has excellent sound cutting effect.

6. Super low temperature resistance

UHMWPE has excellent low temperature resistance and is malleable at liquid helium temperature (-269℃), making it suitable for use as a low temperature resistant component in the nuclear industry.

7. Versatility

UHMWPE is hygienic and non-toxic and can be used in contact with food and drugs.

8. Adsorption power

The surface adsorption capacity of UHMWPE is very weak, and its adhesion resistance is second only to the non-adhesive PTFE in plastic, so the surface of products and other materials are not easy to stick.

9. Molding processing

UHMWPE water absorption is very low; Generally less than 0.01%, only 1% of PA66, so generally do not need to dry before forming processing.

10. Extremely light

The density of UHMWPE is relatively low compared with other engineering plastics.

11. Be flexible

Because UHMWPE has the necessary structural characteristics for tensile orientation, it has unrivably high tensile strength. Therefore, the fibers of ultra-high elastic modulus and strength can be prepared by gel spinning, with the tensile strength up to 3 ~ 3.5GPa and the tensile elastic modulus up to 100 ~ 125GPa. The fiber ratio strength is the highest of all fibers that have been commercialized to date, four times larger than carbon fiber, 10 times larger than steel wire, and 50 percent larger than aramid fiber.

Ultra-high molecular weight polyethylene filter plate is a new type of efficient and energy-saving filter plate after the cast iron filter plate, rubber filter plate, polypropylene filter plate, it has fast dehydration, corrosion resistance, environmental cracking resistance, high compressive strength, impact resistance, light weight, anti-bonding, convenient installation and maintenance, small loss to the filter cloth, long service life and other advantages, the service life is 4-6 times of polypropylene filter plate, Cast iron and rubber filter plate 3-9 times.

Due to the light weight of ultra-high molecular weight polyethylene filter plate (is one eighth of the cast iron filter plate), greatly reduce the load of the filter press girder, prevent the bending deformation of the girder because of the weight of the filter plate, prolong the service life of the girder. The lower pressure of the puller mechanism reduces the impact strength of the filter plate on the press cloth, improves the service life and work efficiency of the puller, press cloth and related hydraulic system, and reduces the labor intensity and maintenance cost of maintenance workers.

UHMWPE extremely high molecular weight gives it excellent performance, and belongs to moderate price, excellent performance of thermoplastic engineering plastics, it almost concentrated the advantages of a variety of plastics, With ordinary polyethylene and other engineering plastics incomparable wear resistance, impact resistance, self-lubrication, corrosion resistance, impact absorption, low temperature resistance, health and non-toxic, not easy to adhere to, not easy to absorb water, low density and other comprehensive properties. In fact, there is no single polymer material with so many excellent properties.

1. High molecular weight

The wear resistance of UHMWPE is the crown of plastics and exceeds that of some metals. The comparison of the wear resistance of UHMWPE and other materials. Compared with other engineering plastics, the sand abrasion index of UHMWPE is only 1/5 of PA66, and 1/10 of HEPE and PVC. Compared to metal, it's 1/7 of carbon steel and 1/27 of brass. Such high wear resistance makes it difficult to test its wear resistance with general plastic wear test method, so a sand abrasion test device is specially designed. The wear resistance of UHMWPE is proportional to the molecular weight, the higher the molecular weight, the better the wear resistance.

2. Extreme impact resistance

The impact strength of UHMWPE is among the best in all engineering plastics. The impact strength of UHMWPE is about 2 times that of impact resistant PC, 5 times that of ABS, and more than 10 times that of POM and PBTP. The impact resistance is so high that it is difficult to fracture by the usual impact test methods. The impact strength increased with the increase of molecular weight, reached the maximum value when the molecular weight was 1.5 million, and then gradually decreased with the increase of molecular weight. It is worth pointing out that it can also maintain excellent impact strength in liquid nitrogen (-195℃), which is not found in other plastics. In addition, it is harder on repeated impact surfaces.

3. Ideal friction

UHMWPE has very low friction coefficient (0.05 ~ 0.11), so it has excellent self-lubrication. The comparison of friction coefficient between UHMWPE and other engineering plastics. UHMWPE dynamic rub factor under water lubrication is PA66 and POM 1/2, under no lubrication conditions second only to plastic in the best self-lubricating polytetrafluoroethylene (PTFE); When it is operated in sliding or rotating form, it is more lubricated than steel and brass with oil. Therefore, in the field of tribology, UHMWPE is regarded as a frictional material with very ideal cost/performance.

4. Chemistry

UHMWPE has excellent chemical resistance, in addition to strong oxidizing acid, in a certain temperature and concentration range of corrosive media (acid, alkali, salt) and organic media (except tea solvent). It was impregnated in 80 organic solvents at 20℃ and 80℃ for 30 days. There was no abnormal appearance and other physical properties were almost unchanged.

5. Silence the sound well

UHMWPE has excellent impact energy absorption, the impact energy absorption value is the highest among all plastics, so the noise damping performance is very good, and has excellent sound cutting effect.

6. Super low temperature resistance

UHMWPE has excellent low temperature resistance and is malleable at liquid helium temperature (-269℃), making it suitable for use as a low temperature resistant component in the nuclear industry.

7. Versatility

UHMWPE is hygienic and non-toxic and can be used in contact with food and drugs.

8. Adsorption power

The surface adsorption capacity of UHMWPE is very weak, and its adhesion resistance is second only to the non-adhesive PTFE in plastic, so the surface of products and other materials are not easy to stick.

9. Molding processing

UHMWPE water absorption is very low; Generally less than 0.01%, only 1% of PA66, so generally do not need to dry before forming processing.

10. Extremely light

The density of UHMWPE is relatively low compared with other engineering plastics.

11. Be flexible

Because UHMWPE has the necessary structural characteristics for tensile orientation, it has unrivably high tensile strength. Therefore, the fibers of ultra-high elastic modulus and strength can be prepared by gel spinning, with the tensile strength up to 3 ~ 3.5GPa and the tensile elastic modulus up to 100 ~ 125GPa. The fiber ratio strength is the highest of all fibers that have been commercialized to date, four times larger than carbon fiber, 10 times larger than steel wire, and 50 percent larger than aramid fiber.

Production technology:

Pressing sintering is the most primitive processing method of ultra high molecular weight polyethylene (UHMW-PE). This method has low production efficiency and is easy to oxidize and degrade. In order to improve production efficiency, direct electric heating can be used.

1. Fusion processing

In addition, Werner and Pfleiderer have developed an ultra-high speed fusion process

2. Blade rotation

Using blade mixer, the maximum speed of blade rotation can reach 150m/s, so that the material can rise to the processing temperature in only a few seconds.

1. Fusion processing

In addition, Werner and Pfleiderer have developed an ultra-high speed fusion process

2. Blade rotation

Using blade mixer, the maximum speed of blade rotation can reach 150m/s, so that the material can rise to the processing temperature in only a few seconds.

Application industry:

The market share of this product has reached 70% in the coal preparation industry and 40% in the mining, metallurgy, chemical industry, waste water treatment and other industries, which has laid a solid foundation for energy saving, consumption reduction and production efficiency improvement in these industries.

Hot Tags:

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy