English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

Products

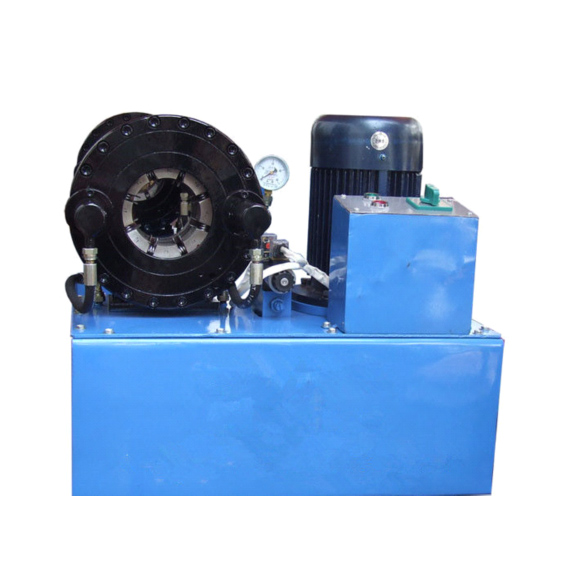

High Pressure Pipe Crimping Machine

Hebei Pude Yuelan Environmental Protection Equipment Co., LTD., is a specialized in High Pressure Pipe Crimping Machine research and development of filter press equipment production enterprises, the company focuses on industrial chimney, tower chimney, self-supporting chimney and filter press, filter plate, pipe machine research and development and production.The working principle of High Pressure Pipe Crimping Machine (schematic diagram of the structure of hose clamping machine).

Send Inquiry

Product Description

High Pressure Pipe Crimping Machine

High Pressure Pipe Crimping Machine is the main equipment for manufacturing hydraulic hose joints. By clamping the connector jacket, the connector jacket, hose and the connector inner core are integrated to form the hydraulic hose connector assembly. At present, the buckle pressure of domestic design and manufacture or press transformation is determined by experience, experiment, analogy and other methods. Therefore, the equipment capacity is too large, volume and weight is too large and other defects and deficiencies. In the process of clamping, there are shortcomings such as unstable clamping quality, low efficiency of shrinking pipe and easy fatigue of operators. The improved crimping machine not only saves manpower, but also improves the crimping quality and pipe shrinking efficiency.

The hydraulic transmission and control system is the main power source of the hose compressor, and the compressor compression process is realized through the hydraulic transmission and control system. The improved design of the mechanical structure and control system of the existing hydraulic high-pressure hose compressor can greatly reduce the overall structure of the compressor, and strive to make the hydraulic transmission and control system as simple as possible. The hydraulic high pressure hose compressor designed in this paper is a kind of pipe machinery which works on the principle of hydraulic transmission. By controlling the expansion of the piston rod of the thrust hydraulic cylinder, the inner cone slider is driven to shrink and release, and the pressure of the high-pressure hose joint is realized.

The hydraulic transmission and control system is the main power source of the hose compressor, and the compressor compression process is realized through the hydraulic transmission and control system. The improved design of the mechanical structure and control system of the existing hydraulic high-pressure hose compressor can greatly reduce the overall structure of the compressor, and strive to make the hydraulic transmission and control system as simple as possible. The hydraulic high pressure hose compressor designed in this paper is a kind of pipe machinery which works on the principle of hydraulic transmission. By controlling the expansion of the piston rod of the thrust hydraulic cylinder, the inner cone slider is driven to shrink and release, and the pressure of the high-pressure hose joint is realized.

First, the basic principle of High Pressure Pipe Crimping Machine combination withholding.

The pressure structure of the hose assembly is generally composed of mountain jacket, hose and core pipe. The leakage of the hose joint refers to the leakage of the coating, hose and core pipe connection part. Therefore, this paper analyzes the coating, hose and core pipe connection part, namely the structure of the tail part of the pipe. The basic principle of high-pressure hose assembly is that the plastic deformation of the jacket under the action of external force leads to the tight adhesion of the rubber layer of the hose and the outer wall of the core tube, so as to complete the seal of the liquid medium in the hose.

(2) Design of High Pressure Pipe Crimping Machine.

Hydraulic high pressure rubber hose press is composed of pump station, hydraulic cylinder, pressure device, guiding mechanism, control system and support frame. The machine consists of an XRB2B emulsion pump matched to a 75kw motor, which converts electrical energy into hydraulic energy of the pump, which then delivers pressure oil to a hydraulic cylinder, which expands as a force for pressure. The piston rod of the hydraulic cylinder is connected with the inner cone slider of the press through the guide mechanism. The double cone surface, the integral valve and the elastic structure buckle die are fixed in the central position between the connecting rod. When the piston rod of the hydraulic cylinder is extended, the inner cone slider of the press is driven forward to clamp the pressure die, that is, the pressure hose; When the piston rod of the hydraulic cylinder retracts, the inner cone slider of the press is driven and the outer cone slider is released to complete the pressure of the hose. In the process of work, the high-pressure liquid of the hydraulic system enters the piston chamber from the left inlet, pushes the piston rod 3 to extend outward, and compresses the outer cone slider 7 of the inner cone slider 6 through the push rod 5, so that the mold elasticity is connected with the hydraulic hose. When the oil is supplied from the right side in reverse, the piston rod shrinks, the cone sleeve releases the compression of the mold, the elasticity of the mold recovers, and the compression cycle of the hose joint is completed. In order to meet the pressure of all different specifications of high pressure hoses and facilitate the replacement of pressure dies, pressure dies are designed into a series of structural forms and related sizes of the same die, but different pressure diameters. In this way, as long as the change of different models of pressure die, can achieve all different specifications of high pressure hose pressure. The pressure of the press directly affects the sealing performance, tensile strength and service life between the hose and the joint. According to the structural characteristics of the hose, the thickness of the tube wall, the mechanical properties of the inner adhesive and the structural type of the joint, the selection of pressure should be considered comprehensively.

(2) Design of High Pressure Pipe Crimping Machine.

Hydraulic high pressure rubber hose press is composed of pump station, hydraulic cylinder, pressure device, guiding mechanism, control system and support frame. The machine consists of an XRB2B emulsion pump matched to a 75kw motor, which converts electrical energy into hydraulic energy of the pump, which then delivers pressure oil to a hydraulic cylinder, which expands as a force for pressure. The piston rod of the hydraulic cylinder is connected with the inner cone slider of the press through the guide mechanism. The double cone surface, the integral valve and the elastic structure buckle die are fixed in the central position between the connecting rod. When the piston rod of the hydraulic cylinder is extended, the inner cone slider of the press is driven forward to clamp the pressure die, that is, the pressure hose; When the piston rod of the hydraulic cylinder retracts, the inner cone slider of the press is driven and the outer cone slider is released to complete the pressure of the hose. In the process of work, the high-pressure liquid of the hydraulic system enters the piston chamber from the left inlet, pushes the piston rod 3 to extend outward, and compresses the outer cone slider 7 of the inner cone slider 6 through the push rod 5, so that the mold elasticity is connected with the hydraulic hose. When the oil is supplied from the right side in reverse, the piston rod shrinks, the cone sleeve releases the compression of the mold, the elasticity of the mold recovers, and the compression cycle of the hose joint is completed. In order to meet the pressure of all different specifications of high pressure hoses and facilitate the replacement of pressure dies, pressure dies are designed into a series of structural forms and related sizes of the same die, but different pressure diameters. In this way, as long as the change of different models of pressure die, can achieve all different specifications of high pressure hose pressure. The pressure of the press directly affects the sealing performance, tensile strength and service life between the hose and the joint. According to the structural characteristics of the hose, the thickness of the tube wall, the mechanical properties of the inner adhesive and the structural type of the joint, the selection of pressure should be considered comprehensively.

Two, hydraulic high pressure hose withholding control.

In the actual production of rubber hose assembly, there is a problem that the preparation process before the problem is too long. In practical applications, it is necessary to conduct several pressure tests and adjust the position of the stroke switch during the first withholding process until the diameter of the jacket meets the requirements after withholding. And some compression quality is difficult to guarantee. Due to the lack of theoretical research on the amount of compression in the hose assembly, no definite adjustment amount can be given when the hose assembly is inconsistent with the standard assembly.

The critical seal contact stress for each hose assembly is a certain value, as is the critical relative compression. In the process of crimping the rubber hose assembly, as long as the relative compression amount reaches the critical relative compression amount, the crimping process can be directly controlled by the connection quality; No need to detect the fit gap between the coat and the steel/rubber composite. During the compression process, four mechanical quantities can be detected online, namely, jacket radial compression, piston rod thrust F, cylinder inlet oil pressure P and core radial compression S. The thrust of the piston rod is consistent with the change law of oil pressure, and the deformation of the hole in the inner sleeve is generally not more than 10 microns. During the clamping process, the assembly has an axial displacement in relation to the measuring head, causing the measuring head to move in the less smooth inner hole. Therefore, the inner hole cannot be measured as a check for compression.

During the compression process of hydraulic high pressure rubber hose, the pressure values show significantly different slope values. Contact stress between the internal rubber and the joint core begins to develop, and this is known as the location of the pressure signature region. Since the critical seal contact stress of each hose assembly is a certain value, the corresponding relative displacement is also a certain value. The critical seal contact stress value can be determined by the pressure characteristic region.

The paper studies the principle of hydraulic hose clamp, designs the mechanical structure of the clamp, analyzes the various working conditions of the hose joint in the process of clamping and the clamping of the hose joint required in the process of clamping, improves the connection quality of the high pressure hose assembly, and puts forward a new idea of making the clamping process according to the principle of plastic machinery. At the same time, on this basis, it provides a theoretical basis for the design of the computer control system.

The critical seal contact stress for each hose assembly is a certain value, as is the critical relative compression. In the process of crimping the rubber hose assembly, as long as the relative compression amount reaches the critical relative compression amount, the crimping process can be directly controlled by the connection quality; No need to detect the fit gap between the coat and the steel/rubber composite. During the compression process, four mechanical quantities can be detected online, namely, jacket radial compression, piston rod thrust F, cylinder inlet oil pressure P and core radial compression S. The thrust of the piston rod is consistent with the change law of oil pressure, and the deformation of the hole in the inner sleeve is generally not more than 10 microns. During the clamping process, the assembly has an axial displacement in relation to the measuring head, causing the measuring head to move in the less smooth inner hole. Therefore, the inner hole cannot be measured as a check for compression.

During the compression process of hydraulic high pressure rubber hose, the pressure values show significantly different slope values. Contact stress between the internal rubber and the joint core begins to develop, and this is known as the location of the pressure signature region. Since the critical seal contact stress of each hose assembly is a certain value, the corresponding relative displacement is also a certain value. The critical seal contact stress value can be determined by the pressure characteristic region.

The paper studies the principle of hydraulic hose clamp, designs the mechanical structure of the clamp, analyzes the various working conditions of the hose joint in the process of clamping and the clamping of the hose joint required in the process of clamping, improves the connection quality of the high pressure hose assembly, and puts forward a new idea of making the clamping process according to the principle of plastic machinery. At the same time, on this basis, it provides a theoretical basis for the design of the computer control system.

Hot Tags: High Pressure Pipe Crimping Machine, China, Manufacturers, Suppliers, Factory, Quotation, Buy, Quality, Made in China, Price, Low Price

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

Related Products

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy