English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

Products

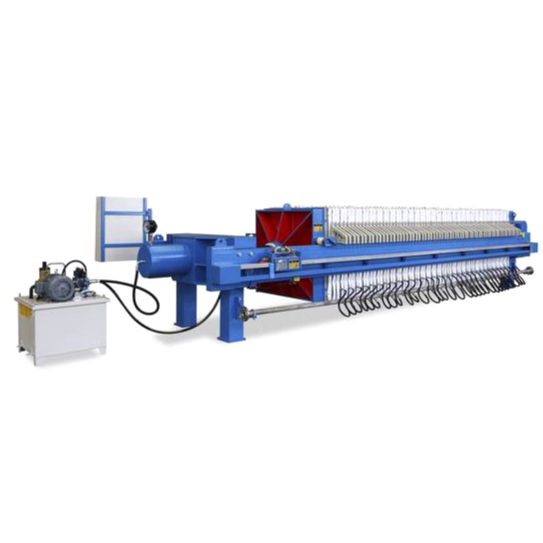

Polymer Elastomer Diaphragm Filter Press

Diaphragm filter press is a kind of filter press installed between the filter plate and the filter cloth with diaphragm equipment, as an important feature of the filter press accessories, its diaphragm due to the model, type of its diaphragm accessories material is also different, rubber diaphragm and polymer diaphragm Generally speaking, from the general category, diaphragm filter press diaphragm classification mainly includes polymer elastomer diaphragm and rubber diaphragm, which is the product of the current development in the past ten years, in the past materials are also different, as a rubber diaphragm, Rubber we all know its properties, in different types of rubber for different substances have different characteristics, usually rubber diaphragm filter press rubber diaphragm is mainly for weak alkali and weak acid filter materials will be more used, but can not be used for organic solvent filter materials, rubber diaphragm in the previous old machine on the split fixed saving energy consumption after the lack of problems, in the current latest product design rubber diaphragm eardrum more sufficient, in the same air volume and air source working conditions environment, The rubber diaphragm tympanic membrane is three times that of the polymer diaphragm tympanic membrane, which plays a lot of role in reducing the energy consumption of the entire machine. And another kind of polymer diaphragm in the industry full name polymer elastomer diaphragm, and the use of the diaphragm filter press is polymer elastomer diaphragm filter press, in general, most of the strong alkali and organic solvent filter material process used more, and the performance is more ideal, and the service life is also considerable, in accordance with different customers need to press components can be configured food grade and ordinary grade, in many equipment have PLC human-computer interface to operate, For ordinary materials, the diaphragm eardrum can fully play the role of pressing and dehydration in about 3-15 minutes, which can be described as twice the result with half the effort. From the perspective of the use of diaphragm filter press, we can see that the diaphragm filter press equipment has achieved a filtration public welfare of efficient dehydration compared with the same type of ordinary equipment, and can also guarantee its own filtration effect to a certain extent, greatly reducing the water content probability of its filter cake, reducing the moisture content of the filter cake while also reducing environmental pollution and reducing the surrounding labor and cost expenditure, saving certain expenses for the enterprise unit.

Send Inquiry

Product Description

Application of Polymer Elastomer Diaphragm Filter Press in rare earth industry:

With the rapid development of rare earth industry, China's rare earth resources are very rich, reserves account for the world's first, for this in recent years the development of many large, medium and small rare earth enterprises, in order to better the rational use of rare earth resources and the extraction of a variety of elements, many enterprises on industrial equipment continuous modification, replacement, reduce energy consumption, the rare earth raw materials further extraction element utilization, the production of more rare earth products.

In recent years, our company after R & D and the practical application of manufacturers, continuous improvement and modification of the quality of equipment technology, specializing in the manufacture of Polymer Elastomer Diaphragm Filter Press for solid-liquid separation in rare earth industry, replacing the original centrifuge solid-liquid separation, reducing energy consumption, low water content of filter cake, reducing enterprise costs, increasing enterprise benefits, and has been widely used in the rare earth industry, well received by the majority of users.

In recent years, our company after R & D and the practical application of manufacturers, continuous improvement and modification of the quality of equipment technology, specializing in the manufacture of Polymer Elastomer Diaphragm Filter Press for solid-liquid separation in rare earth industry, replacing the original centrifuge solid-liquid separation, reducing energy consumption, low water content of filter cake, reducing enterprise costs, increasing enterprise benefits, and has been widely used in the rare earth industry, well received by the majority of users.

First, the technical performance and characteristics of Polymer Elastomer Diaphragm Filter Press:

a) Polymer Elastomer Diaphragm Filter Press structure design is scientific and reasonable, with high mechanical strength, stable structure, durable, easy to operate and maintain. (a) The girder is made of high-quality bridge steel: 10m steel plates are sealed on both sides to make the mechanism more stable and durable; (b) the fixed pressure plate, movable pressure plate and oil bracket are welded with 9345 steel plate, and tempered and flaw detection treatment to eliminate thermal deformation, and are integrated by finishing processing, with large overall strength and no deformation; (c) The pressing mechanism adopts hydraulic pressing method to run smoothly and has a large pressing force, which can ensure that after the source plate is pressed, there is no spraying phenomenon at the sealing of the filter plate when 0.4-0.8MP a passes the source. The pressing pressure can be up to 1.6Mpao

b) Polymer Elastomer Diaphragm Filter Press plate is composed of core plate and membrane plate, the material is different, the core plate is made of modified polytianene and alkali-free glass fiber, the membrane plate is made of polymer TPE material, the core plate and membrane plate composite by special plastic welding machine after high temperature melting and pressure forming, with good elasticity, good sealing performance, no leakage, high strength and other characteristics. The sealing performance between the filter plates is better, and after filtration, the moisture content of the solid is reduced by about 5~10%, depending on the characteristics of the material. The diaphragm life is more than one year.

b) Polymer Elastomer Diaphragm Filter Press plate is composed of core plate and membrane plate, the material is different, the core plate is made of modified polytianene and alkali-free glass fiber, the membrane plate is made of polymer TPE material, the core plate and membrane plate composite by special plastic welding machine after high temperature melting and pressure forming, with good elasticity, good sealing performance, no leakage, high strength and other characteristics. The sealing performance between the filter plates is better, and after filtration, the moisture content of the solid is reduced by about 5~10%, depending on the characteristics of the material. The diaphragm life is more than one year.

Hot Tags:

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy