English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

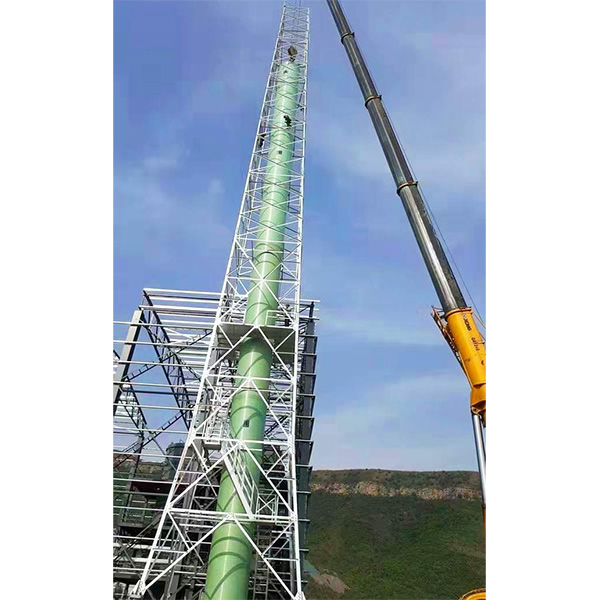

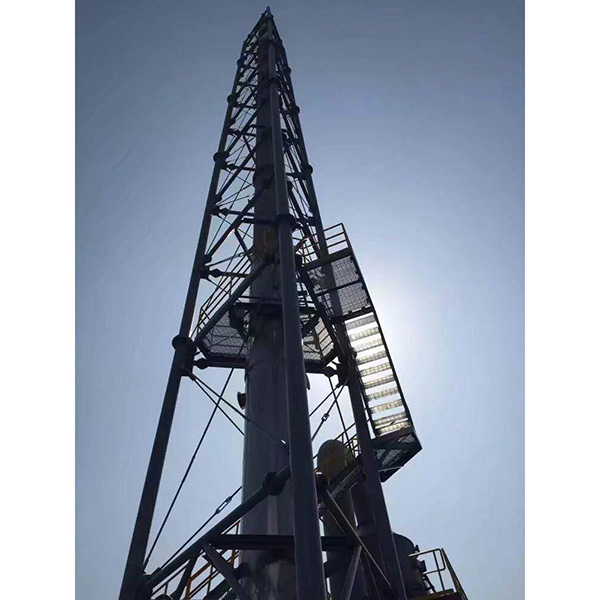

Tower Type Fiberglass Chimney

Hebei Pude Yueland Environmental Protection Equipment Co., Ltd. after years of development in tower type fiberglass chimney and municipal waste treatment equipment industry, the company has become a well-known brand in the industry.

Send Inquiry

Tower Type Fiberglass Chimney

Exhaust emission requirements of all kinds of kiln, boiler, incinerator and other equipment must meet the standards, so the relevant equipment must increase the exhaust treatment facilities, but the chimney as the last end of the exhaust emission equipment, is bound to have an impact, the most important corrosion aspect, traditional materials have been unable to meet the requirements in this respect. A new material called glass reinforced plastic, gradually emerging in various industries, especially in the environmental protection industry, Tower Typle Fiberglass Chimney in recent years, caliber and height is also increasing, the most important is the use of very ideal effect, other materials are not comparable to its superior performance.

The main part of the Tower Typle Fiberglass Chimney is made by winding process, and the FRP products formed by winding are composed of laminate structure. Due to the large length ratio of Tower Typle Fiberglass Chimney, we have developed a complete set of proven and reliable manufacturing and installation processes to ensure chimney installation accuracy (especially verticality). In addition: we can also according to the glass steel chimney diameter size and height can be designed according to customer requirements. At the same time, the shape can also be designed according to the specific requirements of customers. Tower Typle Fiberglass Chimney produced by our factory are now widely used in electric power, chemical fertilizer, chemical industry, smelting, petroleum and other industries, as corrosive or high temperature flue gas treatment equipment.

Due to the high working temperature of many chimneys (generally 50-180℃), the flue gas composition is complex, general resin can not meet its requirements, so the key to choose the lining resin and structural layer resin is whether it can meet the corrosion requirements at high temperature, structural layer resin selection also needs to adapt to high temperature resistance requirements, It is also necessary to consider that the fracture elongation of the structural resin matches that of the lining resin. Considering the convenience of installation, according to the customer's installation requirements, the chimney will be processed in sections, and then assembled on site; The installation process can also be designed according to the wishes of customers.

Hebei Pude Yuelan Environmental Protection Equipment Co., Ltd. is an enterprise engaged in the development and production of industrial chimneys, the company focuses on the development and production of industrial chimneys.

Headquartered in Jingxian Development Zone, Hebei Province, the company has a registered capital of 60 million yuan, covers an area of 9.60000 square meters, of which the building area is 2600 square meters. The main products include self-supporting smoke, sleeve smoke, tower chimney, east smoke, cable smoke, stainless steel chimney, glass steel chimney, mobile compressed garbage bin, horizontal compressed garbage station, hook arm transfer truck, butt type garbage truck and dozens of products. The company has 128 employees, including 8 experts and engineers with master's degree or above, 60% of the employees with bachelor's degree or junior college degree, all kinds of technical personnel 26 people, 60 people special personnel, the company has a number of domestic offices and after-sales service institutions, can provide technical support and product services at any time.

The company's production equipment advanced, strong technical force. Has more than 50 sets of domestic advanced production equipment, including foreign, domestic CNC production lines 6; Hot-dip galvanizing adopts the galvanizing technology and process of Gimeco Company in Italy, and its technical level and production capacity are at the advanced level in China.

After years of development in chimney and municipal waste treatment equipment industry, the company has become a well-known brand in the industry. Through the cooperation with domestic and international design institutes, colleges and enterprises to continuously improve the enterprise's scientific research and development ability. And has cooperated with many universities and reached strategic cooperation with petrochina, Sinopec, Huadian, Huaneng and other enterprises.

In recent years, in order to solve the problem of large-caliber smoke, the company has established a technical cooperation relationship with Beijing Jiaotong University, and invested a lot of manpower and material resources to develop the "precast factory, on-site construction" steel corrugated chimney and urban waste environmental treatment products. At present, the pipe diameter range of the company's products is 0.5m-20m, and the annual production capacity is 660,000 meters.

The company always adhere to the "quality, user" of the enterprise purpose, do not ask for the number of projects, just do the project to make good quality principle, products have been promoted in the project use. Today, the company's products still maintain zero defects, zero complaints, zero accidents, by the owners, construction units of the consistent praise, and establish a long-term cooperative relationship.