English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

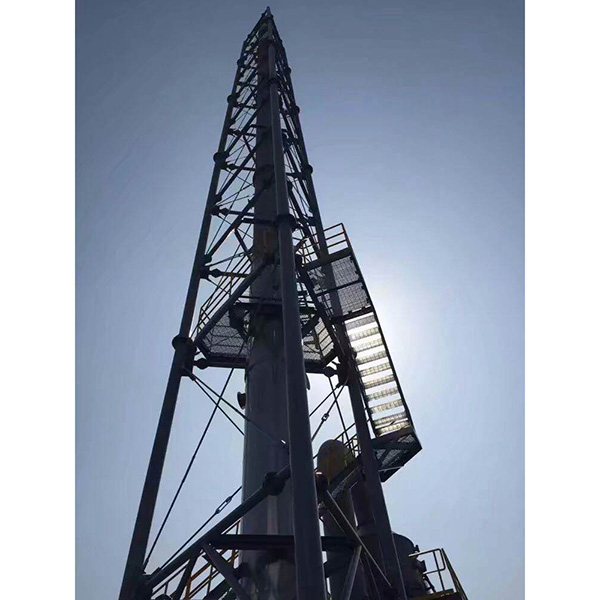

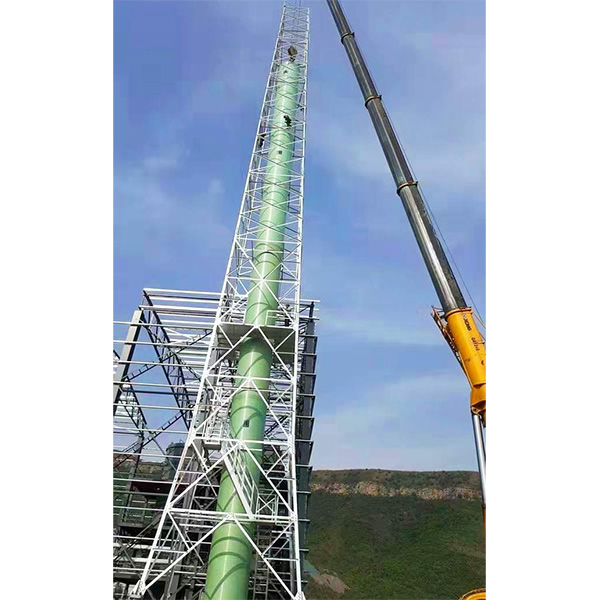

Tower Type Multi-pipe Chimney

Hebei Pude Yueland Environmental Protection Equipment Co., Ltd. after years of development in tower type multi-pipe chimney and municipal waste treatment equipment industry, the company has become a well-known brand in the industry.

Send Inquiry

Tower Type Multi-pipe Chimney

Tower Type Multi-pipe Chimney is mainly composed of smoke pipe, concrete shell (or tower support) and foundation 3 parts. ① Smoke pipe: can be welded with steel plate, can also be cast with reinforced concrete. The smoke pipe with reinforced concrete casting has subsection type and self - standing type. The segmented type is that each smoker is divided into sections supported by floors attached to the concrete shell. The self-supporting type is that each smoke pipe bears its own load. There is a floor every 40 meters between the smoke pipe and the concrete shell, which is used as a channel for maintenance of aviation alarm lights. The chimney can also be constructed in sections of special firebrick, each about 10 meters long, which is supported on the beam between the cow's legs on the concrete shell and the chimney. ② Concrete shell: also known as windshield. It is mainly used to withstand static deflection under wind pressure and dynamic action of eddy currents on the leeward side. When a segmented chimney is used, it can also bear the load of the chimney. The concrete enclosure is generally about 10 meters lower than the smoke pipe and is equipped with a certain number of aviation alarm lights and ventilation Windows. (3) Foundation: caisson type concrete foundation is generally used, and a good foundation is required in order to bear the upper tens of thousands of tons of load. In addition, the inner wall or outer wall of all kinds of smoke pipes need to be laid with different insulation, anti-corrosion materials or anti-corrosion firebrick. The central part of the multi - pipe chimney is generally set up elevator room. All kinds of chimneys need to be equipped with lightning protection devices. A lightning arrester is arranged on the top of the smoke pipe and concrete shell of the multi-pipe chimney, and connected to the crown iron hoops arranged at different rod heights. At the same time, metal conductors are connected to each iron hoops, and then connected to the buried grounding device, forming a lightning protection grounding system. For the multitubular steel chimneys supported by the tower frame, they need only be connected to the earth system.

The advantages of Tower Type Multi-pipe Chimney and sleeve chimney are almost the same. They are made of steel, anti-corrosion, long service life and simple installation.

The disadvantage of the Tower Type Multi-pipe Chimney is that the area is relatively large, too low chimney cost accounting is too high, not fit for the interests of small enterprises!

The disadvantage of telescopic chimney is that the emission speed of telescopic chimney is related to the number of chimney pipes. Within a certain range, the smaller the diameter of chimney pipe, the faster the emission speed of flue gas. In this way, and the construction technology of telescopic chimney is relatively high, and general manufacturers can not do it!

Tower Type Multi-pipe Chimney is a triangular steel structure, the foundation is an equilateral triangle division, and the tower is a four-prism steel structure, the foundation is a quadrangular division. There are round steel chimney tower, Angle steel chimney tower, steel pipe chimney tower. Chimney tower tail gas chimneys have been widely used in many polluting smelting plants, because the Tower Type Multi-pipe Chimney is generally relatively high, in the case of lifting equipment can not meet, generally adopt the hoist with the "inverted rod standing tower method" for installation. It is also necessary to design and calculate the force analysis of the chimney and tower because of the high and heavy components of the tail gas chimney tower, and the safety risks of the lifting work are great when large lifting machinery and equipment cannot be used. Chimney tower construction is a common project in construction engineering, the quality of chimney tower construction directly affects the quality of the whole construction project. Chimney construction is a complete construction process, which includes both the scientific design and the subsequent construction. With the development of economy and society, people have higher and higher requirements for chimney tower construction technology. Under this background, it is very important to strengthen the research on chimney construction.

Hebei Pude Yuelan Environmental Protection Equipment Co., Ltd. is an enterprise engaged in the development and production of industrial chimneys, the company focuses on the development and production of industrial chimneys.

Headquartered in Jingxian Development Zone, Hebei Province, the company has a registered capital of 60 million yuan, covers an area of 9.60000 square meters, of which the building area is 2600 square meters. The main products include self-supporting smoke, sleeve smoke, tower chimney, east smoke, cable smoke, stainless steel chimney, glass steel chimney, mobile compressed garbage bin, horizontal compressed garbage station, hook arm transfer truck, butt type garbage truck and dozens of products. The company has 128 employees, including 8 experts and engineers with master's degree or above, 60% of the employees with bachelor's degree or junior college degree, all kinds of technical personnel 26 people, 60 people special personnel, the company has a number of domestic offices and after-sales service institutions, can provide technical support and product services at any time.

The company's production equipment advanced, strong technical force. Has more than 50 sets of domestic advanced production equipment, including foreign, domestic CNC production lines 6; Hot-dip galvanizing adopts the galvanizing technology and process of Gimeco Company in Italy, and its technical level and production capacity are at the advanced level in China.

After years of development in chimney and municipal waste treatment equipment industry, the company has become a well-known brand in the industry. Through the cooperation with domestic and international design institutes, colleges and enterprises to continuously improve the enterprise's scientific research and development ability. And has cooperated with many universities and reached strategic cooperation with petrochina, Sinopec, Huadian, Huaneng and other enterprises.

In recent years, in order to solve the problem of large-caliber smoke, the company has established a technical cooperation relationship with Beijing Jiaotong University, and invested a lot of manpower and material resources to develop the "precast factory, on-site construction" steel corrugated chimney and urban waste environmental treatment products. At present, the pipe diameter range of the company's products is 0.5m-20m, and the annual production capacity is 660,000 meters.

The company always adhere to the "quality, user" of the enterprise purpose, do not ask for the number of projects, just do the project to make good quality principle, products have been promoted in the project use. Today, the company's products still maintain zero defects, zero complaints, zero accidents, by the owners, construction units of the consistent praise, and establish a long-term cooperative relationship.