English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

Products

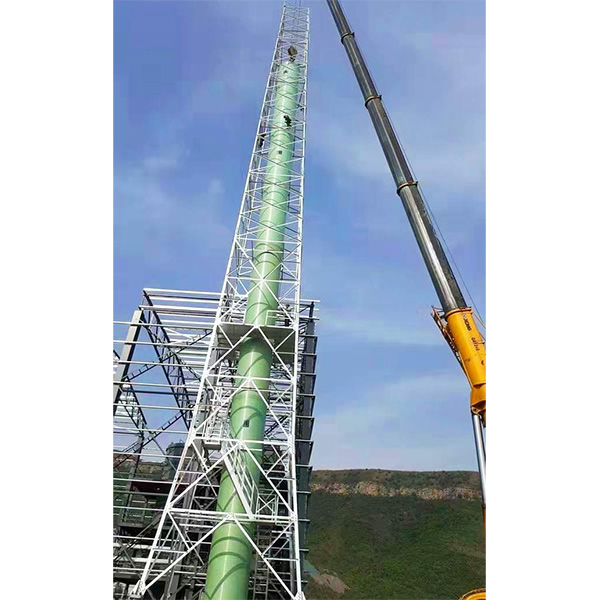

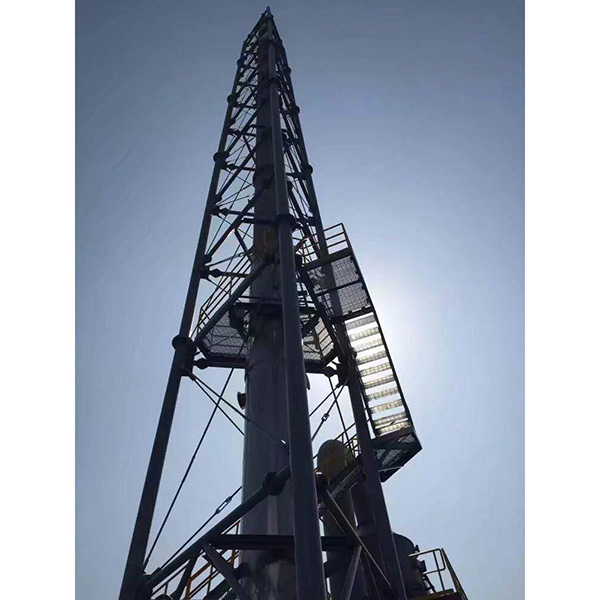

Desulfurization and Degassing Tower Steel Chimney

Hebei Pude Yueland Environmental Protection Equipment Co., Ltd. is a professional engaged in industrial desulfurization and degassing tower steel chimney research and development, production of manufacturers and factories. The company focuses on the development and production of industrial chimneys.

Send Inquiry

Product Description

Desulfurization and degassing tower steel chimney is a new kind of chimney technology, that is, using the aerodynamic characteristics of vortex flow, it can solve the corrosion problem of chimney inner wall after wet desulphurization. At the same time, the new chimney also has better effect of energy saving and environmental protection. This paper systematically discusses the basic connotation, main technical advantages, design points and operation principle of the new chimney technology, and explains the rationality and practical feasibility of the new chimney technology from the aerodynamic principle and engineering practice.

The main function of Desulfurization and Denitration Tower Steel Chimney

The main function of the Desulfurization and Denitration Tower Steel Chimney is to pull out the fire and smoke, discharge the smoke and improve the combustion conditions. Generally, high-rise buildings are equipped with vertical Wells such as stairwells, exhaust ducts, air supply ducts, exhaust ducts, elevator Wells and pipe Wells of varying numbers. When the indoor temperature is higher than the outdoor temperature, the indoor hot air, due to its low density, rises naturally along these vertical channels and seeps through the cracks in doors and Windows and various holes from the upper floors. Outdoor cold air, due to its high density, is supplemented by infiltration from the lower floors. This creates a chimney effect. Chimney effect is the result of the combined action of hot pressure and outdoor wind pressure formed by indoor and outdoor temperature difference, usually the former is the main, and the value of hot pressure is directly proportional to the difference of air density and the height difference of inlet and outlet caused by the temperature difference between indoor and outdoor. This indicates that the higher the indoor temperature is than the outdoor temperature, the higher the building is, and the more obvious the chimney effect is. It also indicates that the chimney effect of civil buildings generally occurs only in winter. As far as a building is concerned, half of the height of the building is regarded as the middle and surface in theory. It is believed that the room below the middle and surface penetrates air from the outside and the room above the middle and surface penetrates air from the inside.

Under the Desulfurization and Denitration Tower Steel Chimney effect, indoor organized natural ventilation and smoke exhaust can be realized, but its negative effects are many: first, the sand blows into the room through various holes and crevices in the lower part, consumes heat and pollutes the room; Secondly, the wind is pumped from the bottom hall door entrance to the top floor through the elevator shaft, resulting in the ladder door can not be closed normally; Third, when a fire occurs, with the sharp rise of indoor air temperature, the volume increases rapidly, and the chimney effect is more obvious. At this time, all kinds of shafts become the vertical channel for pulling out the fire and smoke, which is the main way for the vertical spread of the fire, thus contributing to the expansion of the fire. Data shows that the vertical diffusion speed of the flue gas in the vertical tube well is 3-4m/s, which means that the height of the high-rise building is 100m, the fireworks directly from the bottom to the top floor only about 30s. If the burning conditions were right, the whole building could be in flames in an instant. In order to reduce the negative effects of chimney effect effectively, the following measures can be taken.

Under the Desulfurization and Denitration Tower Steel Chimney effect, indoor organized natural ventilation and smoke exhaust can be realized, but its negative effects are many: first, the sand blows into the room through various holes and crevices in the lower part, consumes heat and pollutes the room; Secondly, the wind is pumped from the bottom hall door entrance to the top floor through the elevator shaft, resulting in the ladder door can not be closed normally; Third, when a fire occurs, with the sharp rise of indoor air temperature, the volume increases rapidly, and the chimney effect is more obvious. At this time, all kinds of shafts become the vertical channel for pulling out the fire and smoke, which is the main way for the vertical spread of the fire, thus contributing to the expansion of the fire. Data shows that the vertical diffusion speed of the flue gas in the vertical tube well is 3-4m/s, which means that the height of the high-rise building is 100m, the fireworks directly from the bottom to the top floor only about 30s. If the burning conditions were right, the whole building could be in flames in an instant. In order to reduce the negative effects of chimney effect effectively, the following measures can be taken.

The main measures to reduce the negative effects of Desulfurization and Denitration Tower Steel Chimney effect:

1. In winter, the air is mainly through a variety of external doors from the bottom into the interior, the most direct way is to all the doors to the outside of the building, as far as possible set into two doors, revolving doors, and install the door or the inside of the outer door set up air curtain, this is particularly necessary for the hall door, for those secondary access along with the underground parking lot of the outside door, in winter also to install doors, At least the door curtain should be thickened. In winter, the ventilation hole at the top of the elevator shaft should be appropriately adjusted to minor or closed.

2. For buildings that have been heated, try not to make the lower part of the indoor temperature higher than the upper part.

3. When a fire occurs, the chimney effect can be generated not only through various shafts in any season, but also on a small scale through air conditioning pipes that cross the floor and even through some unnoticed pores. In this regard, "high-rise civil building design fire Code" (GB50045-1995) has the following clear provisions.

(1) When the enclosure structure is in the form of curtain wall, "the gap between the floor and each floor and the partition wall shall be tightly filled with non-combustible materials".

(2) "The height of the building is not more than 100m high-rise buildings, the cable well, pipeline well should be every 2~3 floors at the floor with the equivalent of the floor fire resistance limit of the non-burning body for fire separation; For high-rise buildings over 100m in height, non-burning bodies equivalent to the fire resistance limit of the floor should be used for fire separation at each floor. All kinds of pores formed by construction defects, bridge and pipe roots must be packed with non-combustion materials.

(3) "The doors of the stairwell and the front room shall be Class B fire doors" and "shall have the function of self-closing"; "The inspection door on the wall of all kinds of vertical tube Wells shall adopt Class C fire door"; "Cable well, pipeline well and room, corridor and other connected holes, the void should be filled with non-combustion materials"; "Fire valves shall be installed on the horizontal pipe section at the junction of the vertical air duct and the horizontal air duct of each layer"; "For vertical exhaust pipes of kitchen, bathroom and toilet, etc., measures should be taken to prevent backflow or fire valves should be set on branch pipes" to ensure the separation of fire from walkways and rooms, and prevent cross spread between floors through shafts.

Hebei Pude Yuelan Environmental Protection Equipment Co., Ltd. is an enterprise engaged in the development and production of industrial chimneys, the company focuses on the development and production of industrial chimneys.

Headquartered in Jingxian Development Zone, Hebei Province, the company has a registered capital of 60 million yuan, covers an area of 9.60000 square meters, of which the building area is 2600 square meters. The main products include self-supporting smoke, sleeve smoke, tower chimney, east smoke, cable smoke, stainless steel chimney, glass steel chimney, mobile compressed garbage bin, horizontal compressed garbage station, hook arm transfer truck, butt type garbage truck and dozens of products. The company has 128 employees, including 8 experts and engineers with master's degree or above, 60% of the employees with bachelor's degree or junior college degree, all kinds of technical personnel 26 people, 60 people special personnel, the company has a number of domestic offices and after-sales service institutions, can provide technical support and product services at any time.

The company's production equipment advanced, strong technical force. Has more than 50 sets of domestic advanced production equipment, including foreign, domestic CNC production lines 6; Hot-dip galvanizing adopts the galvanizing technology and process of Gimeco Company in Italy, and its technical level and production capacity are at the advanced level in China.

After years of development in chimney and municipal waste treatment equipment industry, the company has become a well-known brand in the industry. Through the cooperation with domestic and international design institutes, colleges and enterprises to continuously improve the enterprise's scientific research and development ability. And has cooperated with many universities and reached strategic cooperation with petrochina, Sinopec, Huadian, Huaneng and other enterprises.

In recent years, in order to solve the problem of large-caliber smoke, the company has established a technical cooperation relationship with Beijing Jiaotong University, and invested a lot of manpower and material resources to develop the "precast factory, on-site construction" steel corrugated chimney and urban waste environmental treatment products. At present, the pipe diameter range of the company's products is 0.5m-20m, and the annual production capacity is 660,000 meters.

The company always adhere to the "quality, user" of the enterprise purpose, do not ask for the number of projects, just do the project to make good quality principle, products have been promoted in the project use. Today, the company's products still maintain zero defects, zero complaints, zero accidents, by the owners, construction units of the consistent praise, and establish a long-term cooperative relationship.

2. For buildings that have been heated, try not to make the lower part of the indoor temperature higher than the upper part.

3. When a fire occurs, the chimney effect can be generated not only through various shafts in any season, but also on a small scale through air conditioning pipes that cross the floor and even through some unnoticed pores. In this regard, "high-rise civil building design fire Code" (GB50045-1995) has the following clear provisions.

(1) When the enclosure structure is in the form of curtain wall, "the gap between the floor and each floor and the partition wall shall be tightly filled with non-combustible materials".

(2) "The height of the building is not more than 100m high-rise buildings, the cable well, pipeline well should be every 2~3 floors at the floor with the equivalent of the floor fire resistance limit of the non-burning body for fire separation; For high-rise buildings over 100m in height, non-burning bodies equivalent to the fire resistance limit of the floor should be used for fire separation at each floor. All kinds of pores formed by construction defects, bridge and pipe roots must be packed with non-combustion materials.

(3) "The doors of the stairwell and the front room shall be Class B fire doors" and "shall have the function of self-closing"; "The inspection door on the wall of all kinds of vertical tube Wells shall adopt Class C fire door"; "Cable well, pipeline well and room, corridor and other connected holes, the void should be filled with non-combustion materials"; "Fire valves shall be installed on the horizontal pipe section at the junction of the vertical air duct and the horizontal air duct of each layer"; "For vertical exhaust pipes of kitchen, bathroom and toilet, etc., measures should be taken to prevent backflow or fire valves should be set on branch pipes" to ensure the separation of fire from walkways and rooms, and prevent cross spread between floors through shafts.

Hebei Pude Yuelan Environmental Protection Equipment Co., Ltd. is an enterprise engaged in the development and production of industrial chimneys, the company focuses on the development and production of industrial chimneys.

Headquartered in Jingxian Development Zone, Hebei Province, the company has a registered capital of 60 million yuan, covers an area of 9.60000 square meters, of which the building area is 2600 square meters. The main products include self-supporting smoke, sleeve smoke, tower chimney, east smoke, cable smoke, stainless steel chimney, glass steel chimney, mobile compressed garbage bin, horizontal compressed garbage station, hook arm transfer truck, butt type garbage truck and dozens of products. The company has 128 employees, including 8 experts and engineers with master's degree or above, 60% of the employees with bachelor's degree or junior college degree, all kinds of technical personnel 26 people, 60 people special personnel, the company has a number of domestic offices and after-sales service institutions, can provide technical support and product services at any time.

The company's production equipment advanced, strong technical force. Has more than 50 sets of domestic advanced production equipment, including foreign, domestic CNC production lines 6; Hot-dip galvanizing adopts the galvanizing technology and process of Gimeco Company in Italy, and its technical level and production capacity are at the advanced level in China.

After years of development in chimney and municipal waste treatment equipment industry, the company has become a well-known brand in the industry. Through the cooperation with domestic and international design institutes, colleges and enterprises to continuously improve the enterprise's scientific research and development ability. And has cooperated with many universities and reached strategic cooperation with petrochina, Sinopec, Huadian, Huaneng and other enterprises.

In recent years, in order to solve the problem of large-caliber smoke, the company has established a technical cooperation relationship with Beijing Jiaotong University, and invested a lot of manpower and material resources to develop the "precast factory, on-site construction" steel corrugated chimney and urban waste environmental treatment products. At present, the pipe diameter range of the company's products is 0.5m-20m, and the annual production capacity is 660,000 meters.

The company always adhere to the "quality, user" of the enterprise purpose, do not ask for the number of projects, just do the project to make good quality principle, products have been promoted in the project use. Today, the company's products still maintain zero defects, zero complaints, zero accidents, by the owners, construction units of the consistent praise, and establish a long-term cooperative relationship.

Hot Tags: Desulfurization and Degassing Tower Steel Chimney, China, Manufacturers, Suppliers, Factory, Quotation, Buy, Quality, Made in China, Price, Low Price

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy