English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

Products

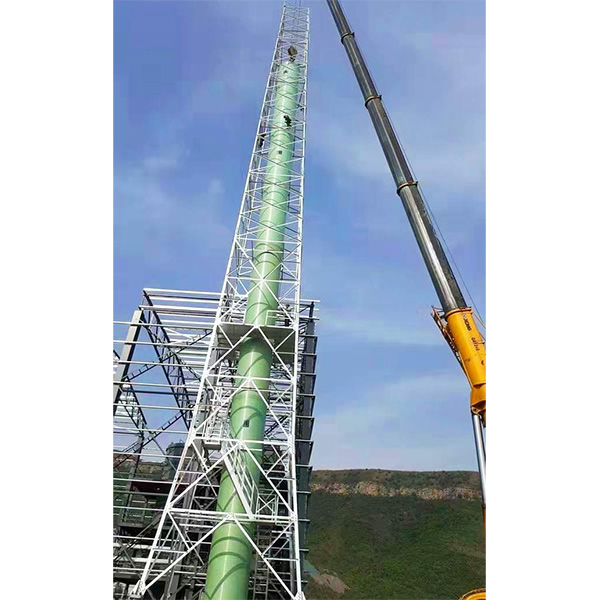

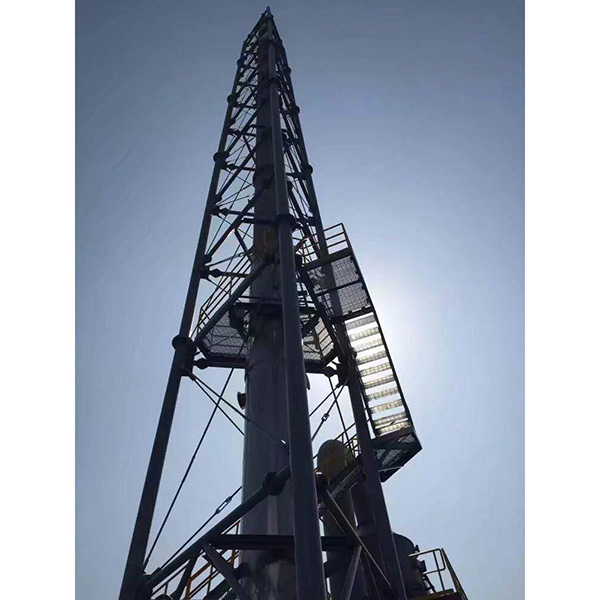

Tower Type Steel Chimney for Waste Incineration Power Generation

The tower type steel chimney for waste incineration power generation of Hebei Pude Yueland Environmental Protection Equipment Co., Ltd. are self-supporting smoke exhaust, sleeve smoke exhaust, tower smoke exhaust, east smoke exhaust, cable smoke exhaust, stainless steel smoke exhaust, glass steel smoke exhaust, mobile compressed garbage can, horizontal compressed garbage station, hook arm transfer vehicle, butt type garbage truck, etc.

Send Inquiry

Product Description

Tower Type Steel Chimney for Waste Incineration Power Generation

Standard waste incineration power plant chimney discharge is after purification to meet the relevant national standards of flue gas, the main components are nitrogen, oxygen, carbon dioxide, and natural air composition materials are basically the same, but because of combustion, the proportion will be different. In addition, there is a much higher proportion of water vapor in the flue gas than in the natural air, because there is more water in the garbage in its original state. At the height of the chimney outlet, when the atmosphere temperature is appropriate, this part of the vapor is not visible and appears as smoke. At night, when the ambient temperature drops, this part of the water vapor condenses and appears as smoke. There is no absolute thing in the world, there will be a very small amount of dust inside the smoke and so on can not be completely removed. Therefore, it is not that there is no pollution at all, but the pollutants are very small, which meet the relevant national standards and are within the allowable environmental influence range.

What are the main components of the flue gas produced after waste incineration?

In addition to dust, sulfur dioxide, carbon dioxide and nitrogen oxides, there are also hydrogen fluoride, hydrogen chloride, furan and dioxins in the flue gas after waste incineration. These harmful components will be treated and removed by advanced technological means, and finally discharged through the chimney are in line with the national Circular [2008]82 standard, which has basically no impact on the environment.

Waste bai gas discharged by waste incineration power plant mainly comes from the flue gas zhi produced by incinerator. The main pollutants contained in the BAI gas are dust dao, hydrogen chloride (HCl), sulfur dioxide (SO2), nitrogen oxides (NOX), carbon monoxide (CO), hydrogen fluoride (HF), organic pollutants, dioxins and heavy metals.

Gasboard continuous monitoring system for flue gas emissions from fixed pollution sources can dynamically and continuously monitor pollutants such as particulate matter, SO2, NOx in the flue gas, measure the flow rate, pressure, temperature, humidity, oxygen content and other data of the flue gas, and automatically record the total amount of pollutant emissions and discharge time. The monitoring data is transmitted to the management department through PSTN, GPRS, CDMA and other communication means to realize the remote real-time monitoring of pollution source emissions

Two furnaces of 2×135MW unit # phase project of the power plant share A chimney, the design elevation is ±0.00m, equivalent to the elevation of 4.5m(85 national elevation), the central coordinate A=710.77, B=1134.08, the height of the chimney is 210m, the diameter of the top outlet is 5.6m, the diameter of the outside is 17.0m at ±0.0m. The elevation of the ash accumulation platform is 8.9m, and the signal platform outside the chimney is on the second floor, with the elevation of 125.0m and 173.5m respectively. The external ladder is located in the northeast direction, the chimney 108-180m is painted with 5m of red and white aviation logo paint, the chimney is made of acid-resistant clay masonry firebrick, the heat insulation layer is made of water-soluble expanded perlite, masonry with special perlite binder, four detection holes are arranged at both sides of the barrel, the elevation of which are 25.0m, 75.0m, 126.50m, 175.0m, respectively. A settlement observation mark is set at 0.5m of the barrel body, and four tilt observation marks are set at 175m.

Hebei Pude Yuelan Environmental Protection Equipment Co., Ltd. is an enterprise engaged in the development and production of tower type steel chimney for Waste Incineration Power Generation, the company focuses on the development and production of industrial chimneys.

Headquartered in Jingxian Development Zone, Hebei Province, the company has a registered capital of 60 million yuan, covers an area of 9.60000 square meters, of which the building area is 2600 square meters. The main products include self-supporting smoke, sleeve smoke, tower chimney, east smoke, cable smoke, stainless steel chimney, glass steel chimney, mobile compressed garbage bin, horizontal compressed garbage station, hook arm transfer truck, butt type garbage truck and dozens of products. The company has 128 employees, including 8 experts and engineers with master's degree or above, 60% of the employees with bachelor's degree or junior college degree, all kinds of technical personnel 26 people, 60 people special personnel, the company has a number of domestic offices and after-sales service institutions, can provide technical support and product services at any time.

The company's production equipment advanced, strong technical force. Has more than 50 sets of domestic advanced production equipment, including foreign, domestic CNC production lines 6; Hot-dip galvanizing adopts the galvanizing technology and process of Gimeco Company in Italy, and its technical level and production capacity are at the advanced level in China.

After years of development in chimney and municipal waste treatment equipment industry, the company has become a well-known brand in the industry. Through the cooperation with domestic and international design institutes, colleges and enterprises to continuously improve the enterprise's scientific research and development ability. And has cooperated with many universities and reached strategic cooperation with petrochina, Sinopec, Huadian, Huaneng and other enterprises.

In recent years, in order to solve the problem of large-caliber smoke, the company has established a technical cooperation relationship with Beijing Jiaotong University, and invested a lot of manpower and material resources to develop the "precast factory, on-site construction" steel corrugated chimney and urban waste environmental treatment products. At present, the pipe diameter range of the company's products is 0.5m-20m, and the annual production capacity is 660,000 meters.

The company always adhere to the "quality, user" of the enterprise purpose, do not ask for the number of projects, just do the project to make good quality principle, products have been promoted in the project use. Today, the company's products still maintain zero defects, zero complaints, zero accidents, by the owners, construction units of the consistent praise, and establish a long-term cooperative relationship.

Waste bai gas discharged by waste incineration power plant mainly comes from the flue gas zhi produced by incinerator. The main pollutants contained in the BAI gas are dust dao, hydrogen chloride (HCl), sulfur dioxide (SO2), nitrogen oxides (NOX), carbon monoxide (CO), hydrogen fluoride (HF), organic pollutants, dioxins and heavy metals.

Gasboard continuous monitoring system for flue gas emissions from fixed pollution sources can dynamically and continuously monitor pollutants such as particulate matter, SO2, NOx in the flue gas, measure the flow rate, pressure, temperature, humidity, oxygen content and other data of the flue gas, and automatically record the total amount of pollutant emissions and discharge time. The monitoring data is transmitted to the management department through PSTN, GPRS, CDMA and other communication means to realize the remote real-time monitoring of pollution source emissions

Two furnaces of 2×135MW unit # phase project of the power plant share A chimney, the design elevation is ±0.00m, equivalent to the elevation of 4.5m(85 national elevation), the central coordinate A=710.77, B=1134.08, the height of the chimney is 210m, the diameter of the top outlet is 5.6m, the diameter of the outside is 17.0m at ±0.0m. The elevation of the ash accumulation platform is 8.9m, and the signal platform outside the chimney is on the second floor, with the elevation of 125.0m and 173.5m respectively. The external ladder is located in the northeast direction, the chimney 108-180m is painted with 5m of red and white aviation logo paint, the chimney is made of acid-resistant clay masonry firebrick, the heat insulation layer is made of water-soluble expanded perlite, masonry with special perlite binder, four detection holes are arranged at both sides of the barrel, the elevation of which are 25.0m, 75.0m, 126.50m, 175.0m, respectively. A settlement observation mark is set at 0.5m of the barrel body, and four tilt observation marks are set at 175m.

Hebei Pude Yuelan Environmental Protection Equipment Co., Ltd. is an enterprise engaged in the development and production of tower type steel chimney for Waste Incineration Power Generation, the company focuses on the development and production of industrial chimneys.

Headquartered in Jingxian Development Zone, Hebei Province, the company has a registered capital of 60 million yuan, covers an area of 9.60000 square meters, of which the building area is 2600 square meters. The main products include self-supporting smoke, sleeve smoke, tower chimney, east smoke, cable smoke, stainless steel chimney, glass steel chimney, mobile compressed garbage bin, horizontal compressed garbage station, hook arm transfer truck, butt type garbage truck and dozens of products. The company has 128 employees, including 8 experts and engineers with master's degree or above, 60% of the employees with bachelor's degree or junior college degree, all kinds of technical personnel 26 people, 60 people special personnel, the company has a number of domestic offices and after-sales service institutions, can provide technical support and product services at any time.

The company's production equipment advanced, strong technical force. Has more than 50 sets of domestic advanced production equipment, including foreign, domestic CNC production lines 6; Hot-dip galvanizing adopts the galvanizing technology and process of Gimeco Company in Italy, and its technical level and production capacity are at the advanced level in China.

After years of development in chimney and municipal waste treatment equipment industry, the company has become a well-known brand in the industry. Through the cooperation with domestic and international design institutes, colleges and enterprises to continuously improve the enterprise's scientific research and development ability. And has cooperated with many universities and reached strategic cooperation with petrochina, Sinopec, Huadian, Huaneng and other enterprises.

In recent years, in order to solve the problem of large-caliber smoke, the company has established a technical cooperation relationship with Beijing Jiaotong University, and invested a lot of manpower and material resources to develop the "precast factory, on-site construction" steel corrugated chimney and urban waste environmental treatment products. At present, the pipe diameter range of the company's products is 0.5m-20m, and the annual production capacity is 660,000 meters.

The company always adhere to the "quality, user" of the enterprise purpose, do not ask for the number of projects, just do the project to make good quality principle, products have been promoted in the project use. Today, the company's products still maintain zero defects, zero complaints, zero accidents, by the owners, construction units of the consistent praise, and establish a long-term cooperative relationship.

Hot Tags: Tower Type Steel Chimney for Waste Incineration Power Generation, China, Manufacturers, Suppliers, Factory, Quotation, Buy, Quality, Made in China, Price, Low Price

Send Inquiry

Please feel free to fill your inquiry in the form below. We will reply you in 24 hours.

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy